Power quality of medical equipment

Ensuring Power Quality for Medical Equipment: A Crucial Safeguard

The healthcare industry relies heavily on sophisticated medical equipment to diagnose, treat, and monitor patients. Ensuring the consistent and reliable operation of this equipment is paramount to delivering optimal patient care. This is where the concept of power quality comes into play.

What is Power Quality?

Power quality refers to the characteristics of the electrical power supply, including voltage, current, and frequency. These characteristics must be within specific limits for sensitive medical equipment to function properly. Poor power quality can lead to equipment malfunctions, data loss, and even patient safety hazards.

Common Power Quality Issues in Hospitals

Several factors can contribute to poor power quality in hospitals, including:

- Harmonic distortion: This occurs when electrical loads draw non-sinusoidal currents, causing voltage distortion.

- Voltage fluctuations: This can be caused by power surges, sags, and brownouts.

- Frequency variations: Deviations from the standard frequency of 60 Hz can disrupt the operation of sensitive equipment.

- Transient events: These are short-duration disturbances, such as spikes, dips, and surges, that can damage equipment and disrupt operations.

The Impact of Poor Power Quality on Medical Equipment

Poor power quality can have a significant impact on medical equipment, leading to:

- Equipment malfunctions: This can lead to inaccurate diagnoses, delayed treatment, and even life-threatening situations.

- Data loss: Critical patient data can be lost due to power outages or equipment malfunctions.

- Reduced lifespan of equipment: Frequent power disturbances can shorten the lifespan of expensive medical equipment.

- Increased maintenance costs: Troubleshooting and repairing problems caused by poor power quality can be costly.

Problems faced

Power quality can impact the cleanliness and stability of critical medical equipment. Diagnosing power quality problems can be time consuming without the right tools.

How we solve that problem

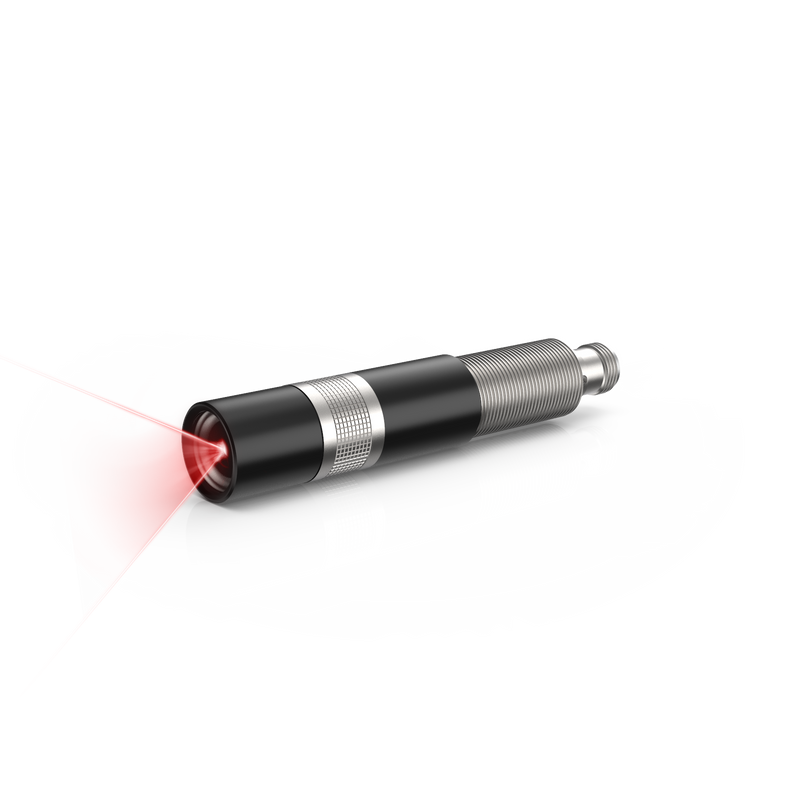

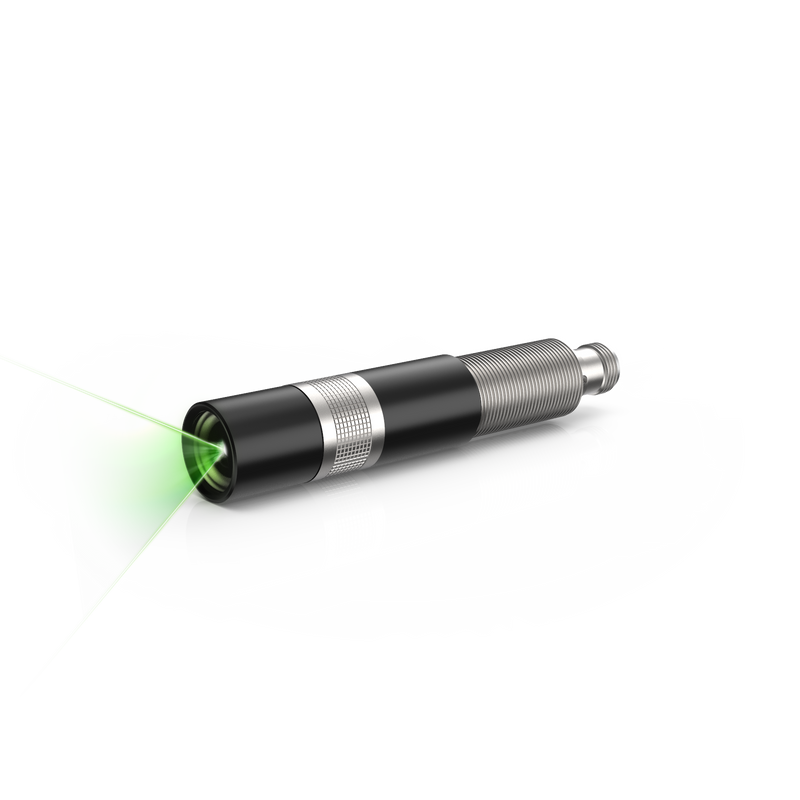

Fluke Three-Phase Power Quality Loggers provide long-term analyses and perform power quality surveys on critical equipment.

Strategies for Maintaining Power Quality in Hospitals

Several strategies can be implemented to ensure power quality for medical equipment, including:

- Installing power conditioners: These devices can help to regulate voltage, filter out harmonics, and protect equipment from transient events.

- Implementing backup power systems: Uninterruptible power supplies (UPS) can provide immediate backup power during outages.

- Monitoring power quality: Regularly monitoring power quality levels can help identify and address potential problems before they cause disruptions.

- Investing in preventive maintenance: Regularly inspecting and maintaining electrical systems can help to prevent problems and improve reliability.

Maintaining power quality is essential for ensuring the safe and reliable operation of medical equipment. By understanding the potential risks associated with poor power quality and implementing effective mitigation strategies, hospitals can create a safe and reliable environment for patients and staff.