Laser assisted Positioning Table

Laser-Assisted Positioning Tables: A Beacon of Precision in Manufacturing and More

The world of manufacturing thrives on accuracy, and often, millimeters, or even microns, can make all the difference. Achieving such extreme precision consistently can be a challenge, but that's where laser-assisted positioning tables step in, shining a light on a new era of control.

But what exactly are these specialized tables, and how are they revolutionizing various industries?

The Guiding Light: How Laser-Assisted Positioning Works

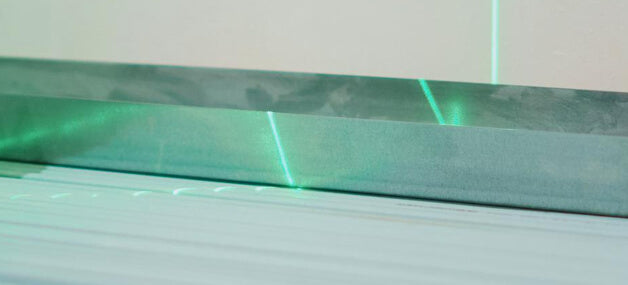

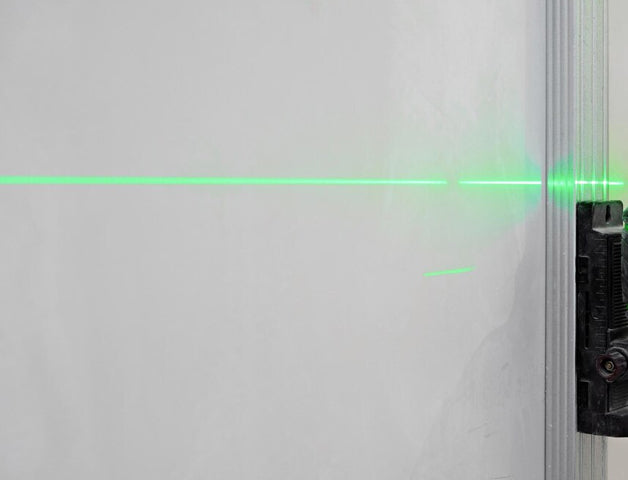

Unlike traditional positioning tables that rely on mechanical systems, laser-assisted tables incorporate lasers to project reference points or lines onto the work surface. These lines serve as visual guides, allowing operators to position components with unparalleled accuracy.

There are two main types of laser-assisted positioning systems:

- Cross-laser systems: Project two perpendicular laser lines, creating a precise crosshair for alignment.

- Line laser systems: Emit a single, straight laser line, ideal for guiding linear movements or edge alignment.

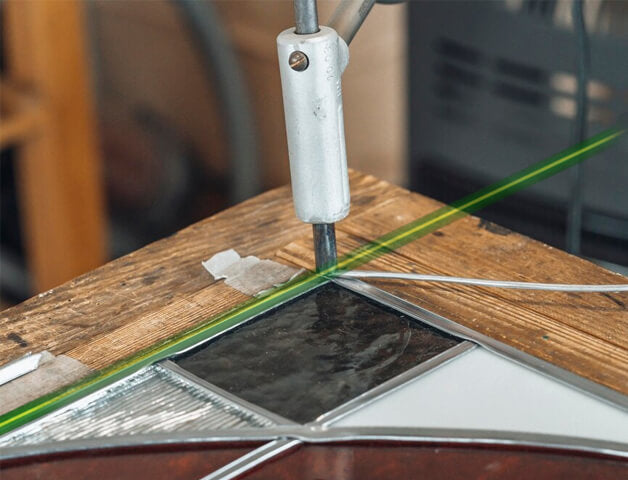

Cross-lasers or line lasers facilitate the pattern-accurate overlapping of fabrics so that all the cut pieces are created with the same pattern.

Beyond Manufacturing: A Range of Applications

- Micromachining and laser cutting: Precisely guiding laser beams for intricate detail work.

- Welding and soldering: Ensuring perfect component alignment for strong, reliable joints.

- Assembly and inspection: Streamlining manual tasks with visual cues for accurate placement and quality control.

Cross-lasers or line lasers facilitate the pattern-accurate overlapping of fabrics so that all the cut pieces are created with the same pattern.

Their applications extend far beyond, finding use in:

- Textile industry: Aligning fabric layers for accurate cutting and pattern matching.

- Construction and woodworking: Precisely positioning beams and other structural elements.

- Medical device manufacturing: Ensuring the minutest components are placed with utmost accuracy.

- Research and development: Facilitating delicate experiments and measurements in various fields.

Advantages that Shine Through

Laser-assisted positioning tables offer several advantages over traditional methods:

- Enhanced accuracy: Achieve micron-level precision, surpassing mechanical limitations.

- Improved efficiency: Faster setup and reduced errors translate to higher productivity.

- Reduced eye strain: Eliminate the need for manual measurements, minimizing fatigue.

- Greater flexibility: Adapt to various workflows and workpiece sizes with ease.

- Visual confirmation: Provides real-time feedback for accurate positioning.

Special Uses:

- High acuteness of projections, even on large work surfaces

- High resistance to dust

- Good visibility of laser light on all materials without health risks

- Advantages:

Patterns and grains are accounted for in the placement of material - More precise results and Higher efficiency

The Future Looks Bright

As technology advances, laser-assisted positioning tables are poised to become even more sophisticated and versatile. Integration with automation systems, enhanced software control, and the use of different laser wavelengths are just a few exciting possibilities.

With their unmatched precision, efficiency, and ease of use, laser-assisted positioning tables are not just tools; they are beacons guiding the way towards a future of smarter, more precise manufacturing and beyond.